Bulk material conveying systems

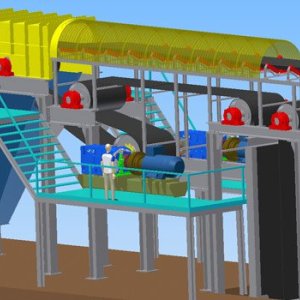

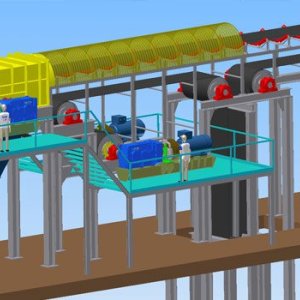

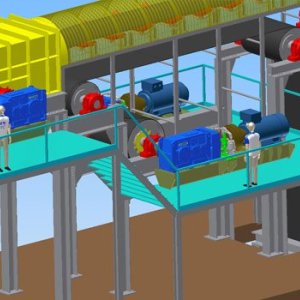

Trough belt conveyors

Belt conveyors in today’s bulk material conveying systems are most commonly used due to their construction and economical aspects.

Relatively simple construction, high reliability and ease of operation have made the belt conveyors the primary means of transport of bulk materials.

Long distance conveyors are sub-class of belt conveyors. They are single flight conveyors of long lengths having the possibility to transport not only straight, but also along horizontal and vertical curves, adjusting to the land configuration.

Power rating of their electrical drives is considerably higher and reaches several MW.

Today’s longest conveying lines reach up to 20 km.

- Possibility of sharp angle of conveyor inclination

- High capacity

- High belt speed

Pipe conveyors

The construction of the pipe conveyor is similar to the conventional through conveyors, namely they consist of a drive station with the drum drive, return drive with return the drum and tensioning system. They vary in shape and construction from the thorough belt conveyor. The pipe conveyor has a bending zone in which the upper belt is formed into a tubular shape and the bottom belt returns to original shape. The part of the conveyor route along which the belt is in the tubular form may have horizontal or vertical bends, as well as their spatial combination.

The application of the pipe conveyors in transport allows to :

- eliminate spillage of transported material improving ecology,

- use routes with spatial bends eliminating the need to build multi conveyor transport systems,

- increase the conveyor inclination by approx. 50% (due to the closure of the material transported in the pipe)

- Pipe diameter: from 150 to 600mm

- Length: up to 10 km

- Efficiency: up to 800 m3/h

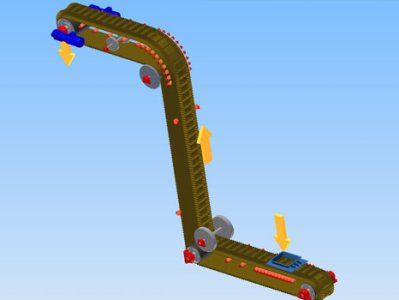

Vertical belt conveyors

The idea of transport in this type of conveyor is based on a special belt. This belt is made of a base belt (similar to that in trough conveyors), with two sidewalls and cleats between them forming a kind of buckets, in which material is transported. The second type of belt used in this type of belt conveyors is the pocket belt consisting of, the base belt with attached pockets in which material is transported.

These conveyors can lift material vertically to great heights and at different angles, occupying relatively little space. They require much less energy and are less noisy compared to traditional bucket conveyors.

- belt width from 600 to 2000m

- efficiency 6000 t/h

- raising height to 300 m